Ebonite is vulcanized rubber

When vulcanized in hot steam, rubber’s soft structures are crosslinked by sulphur molecules and thus a material is created which is flexible yet dimensionally stable.

When vulcanized in hot steam, rubber’s soft structures are crosslinked by sulphur molecules and thus a material is created which is flexible yet dimensionally stable.

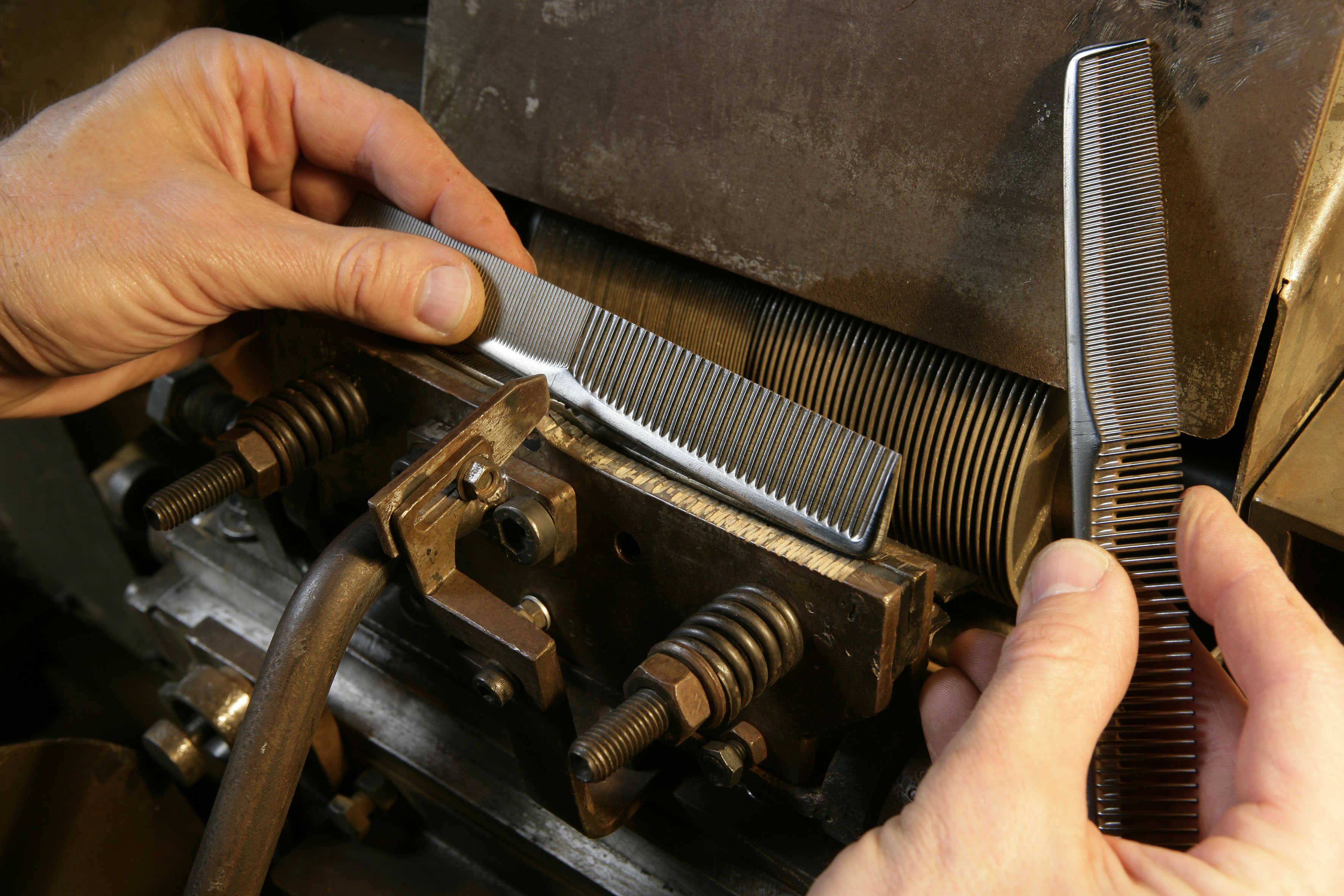

The natural rubber is pressed between tin foil and the comb mold. After vulcanization, the tin foil is removed and ebonite has formed from the soft rubber.

The comb sheets are then worked by hand (grinding, sawing, and polishing) whereby the surface quality as well as the precision of the tooth-cutting are constantly monitored so that only faultless combs without any hair damaging burrs leave our factory.

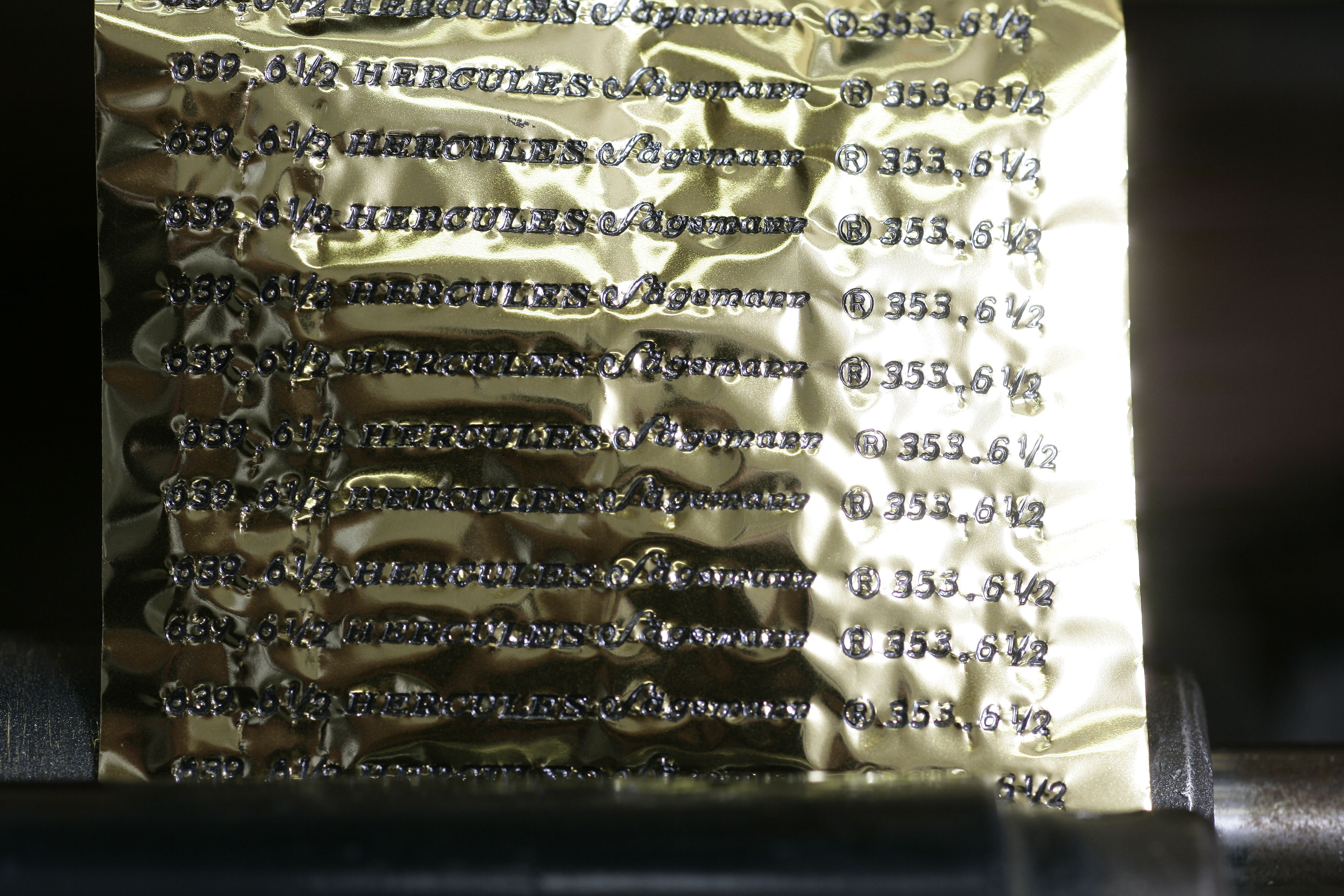

Finally, the comb is embossed in real gold with the world famous ‘Hercules Sagemann’, the brand which guarantees the highest quality, functional design, and maximum hair protection.